The role of Aluminum Casting Company in optimizing manufacturing processes

Check Out Ingenious Foundry Services That Enhance Manufacturing Effectiveness

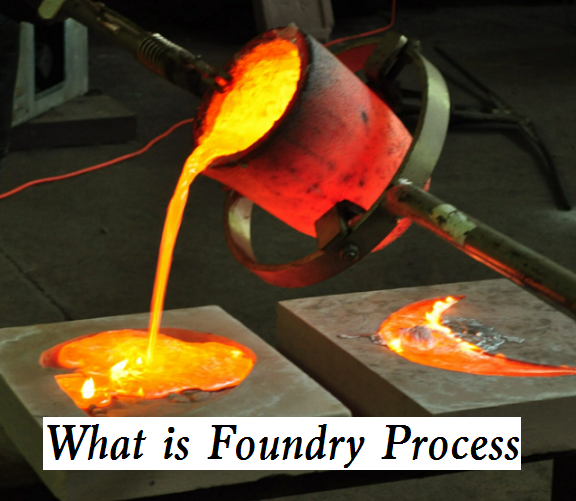

Ingenious foundry services are improving the landscape of producing effectiveness. Advanced casting methods, wise automation, and sustainable methods are at the leading edge of this transformation. Business are now leveraging innovations like 3D printing and AI to improve processes. As these methods gain traction, the concern develops: exactly how will these advancements impact total manufacturing top quality and timelines? The answer hinges on checking out the key components driving this advancement.

Advanced Casting Techniques Reinventing Production

Advanced casting strategies are transforming the landscape of manufacturing in the foundry market. These innovations make it possible for producers to generate complicated forms with boosted precision, minimizing material waste and enhancing general efficiency. Strategies such as financial investment casting, lost foam casting, and 3D printing are obtaining grip, enabling for intricate designs that were previously unattainable.

Improvements in mold-making processes, consisting of the usage of sophisticated products and computer system simulations, have structured manufacturing timelines. These techniques not just enhance the quality of the end product however also facilitate quicker prototyping and shorter preparations.

The combination of these advanced casting techniques supports sustainability in the foundry market by decreasing power consumption and exhausts. As the industry continues to advance, these innovations are establishing new requirements for top quality and performance, inevitably causing better competitiveness in the global market. This shift symbolizes a turning point in the foundry industry, assuring a future of improved abilities and reduced environmental influence.

The Role of Smart Automation in Foundry Services

As the foundry market welcomes technical innovations, wise automation is playing a necessary function in improving operational efficiency and product quality. The integration of automated systems, such as robot arms and AI-driven surveillance, improves procedures by minimizing human mistake and labor prices. These innovations enable accurate control over manufacturing specifications, making sure consistency in item result.

Additionally, wise automation facilitates real-time data collection and analysis, enabling aggressive upkeep and faster decision-making. By utilizing anticipating analytics, factories can anticipate tools failings and optimize manufacturing routines, thereby minimizing downtime. In enhancement, automation adds to enhanced safety and security in the work environment by taking control of harmful tasks, permitting proficient workers to concentrate on more intricate operations.

Lasting Practices in Modern Foundries

The foundry market is increasingly acknowledging the significance of sustainability along with the improvements brought by clever automation. Modern foundries are taking on environment-friendly techniques that decrease waste and decrease carbon footprints. These campaigns consist of executing energy-efficient machinery, using recyclable products, and enhancing production processes to save sources.

Additionally, lots of shops are exploring alternative energy sources, such as solar and wind power, to more decrease their environmental influence. The combination of digital technologies makes it possible for accurate monitoring of source usage, enabling real-time changes that promote sustainability.

Moreover, water preservation techniques are being Website utilized, consisting of closed-loop systems that reuse water used in cooling and cleaning processes. By prioritizing sustainable practices, factories not just abide by regulatory requirements however likewise enhance their one-upmanship in a market progressively concentrated on ecological duty. This change in the direction of sustainability stands for a significant evolution in the foundry sector, aligning operational efficiency with ecological stewardship.

Enhancing High Quality Control With Cutting-edge Solutions

Ingenious solutions are transforming top quality control procedures within the foundry market, guaranteeing that products satisfy strict standards and requirements. The assimilation of advanced evaluation technologies, such as automated visual inspection systems and non-destructive screening techniques, has significantly enhanced the capacity to identify issues early in the manufacturing cycle. These technologies enable real-time surveillance, permitting prompt rehabilitative actions and reducing waste.

Furthermore, collaborative systems facilitate communication amongst quality assurance teams, fostering a culture of constant renovation. As an outcome, innovative high quality control services not just boost product reliability yet likewise add to total operational efficiency, making sure that shops maintain their affordable side in the sector.

Integrating Industry 4.0 Technologies in Manufacturing Processes

Incorporating Sector 4.0 modern technologies into manufacturing procedures stands for a considerable development for factories looking for to enhance performance and performance (Aluminum Foundry). These modern technologies include the Net of Points (IoT), artificial knowledge (AI), and progressed information analytics, enabling for real-time surveillance and control of manufacturing systems. By executing smart sensing units and linked equipment, factories can optimize procedures, lower downtime, and proactively address maintenance requirements

AI-driven analytics enable makers to enhance and forecast trends decision-making, resulting in structured operations and reduced waste. Automation of repetitive tasks further improves operational efficiency, freeing experienced workers to concentrate on complex analytical.

Frequently Asked Inquiries

What Are the Trick Conveniences of Outsourcing Foundry Services?

Outsourcing foundry services offers many advantages, including expense savings, accessibility to specific competence, boosted production capability, lowered lead times, and boosted flexibility. These advantages allow firms to concentrate on core expertises while enhancing operational efficiency.

Just How Do Foundry Services Impact General Production Prices?

Foundry services substantially impact overall manufacturing prices by enhancing product usage, decreasing labor expenses, and enhancing manufacturing rate. These efficiencies result in decrease operational costs and enhanced revenue margins for producers in open markets.

What Industries Advantage Most From Cutting-edge Foundry Services?

Industries such as auto, aerospace, and customer electronics considerably take advantage of ingenious foundry services. These markets leverage advanced techniques to enhance item high quality, reduce have a peek here preparations, and lower manufacturing prices, therefore enhancing overall functional performance.

Just How Can Small Manufacturers Access Advanced Foundry Technologies?

Little makers can access sophisticated foundry innovations via partnerships with larger factories, leveraging cloud-based systems for design and simulation, and taking part in sector partnerships that supply sources, understanding sharing, and financial backing for technology fostering.

What Accreditations Should a Credible Foundry Company Have?

A respectable foundry provider should possess accreditations such as ISO 9001 for high quality monitoring, ISO 14001 for ecological administration, and industry-specific qualifications like AS9100 for aerospace, making sure adherence to high standards and regulative compliance. (aluminum casting)

As the foundry industry accepts technical developments, smart automation is playing a necessary function in enhancing operational efficiency and product high quality. By prioritizing lasting methods, factories not only comply with governing requirements however also boost their affordable edge in a market increasingly concentrated on ecological responsibility. Incorporating Sector 4.0 innovations right into producing processes stands for a considerable advancement for shops seeking to enhance performance and performance. Contracting out foundry services provides numerous advantages, including price financial savings, useful reference access to specialized knowledge, increased manufacturing capacity, lowered lead times, and improved adaptability. Foundry services significantly influence general manufacturing expenses by maximizing material use, decreasing labor expenditures, and boosting production rate.